Aspect ratio is the ratio of wing span to its aerodynamic breadth or chord. For most wings the length of the chord is not a constant but varies along the wing, so the aspect ratio AR is defined as the square of the wingspan divided by the area of the wing planform. (Ref: Wikipedia)

I can go on with formulas and other technical details. But let's not get caught up in various representation. What exactly is aspect ratio? What does it do?

Aspect ratio tells you how the wings perform aerodynamically.

By looking at the value of aspect ratio, you can tell if the wings produce more lift or not.

Simply put, if the value of aspect ratio is high then the wings produce more lift.

If the value of aspect ratio is low, then those wings produce less lift.

Why is it like that?

Check out the picture below:

Aspect Ratio of A = 4

Aspect Ratio of B = 25

And both have same wing area.

Still the shape is different. Why?

Again, look at the picture below:

It's the Solar Impulse 2 and an A330. Both have different aspect ratios. Solar impulse has high aspect ratio while A330 has lower aspect ratio. Why?

It is to get higher lift to drag ratio.

Simply put, the lift should be higher than drag. Of course all the aircraft have a positive lift to drag ratio otherwise they won't fly. But we can increase the value of lift while keeping drag value at bay, so that at higher lift to drag ratio, the aircraft produces tremendous lift force.

But if we increase lift the drag also increases. After all their parameters are same.

How do we increase lift but not drag?

That is where aspect ratio kicks in.

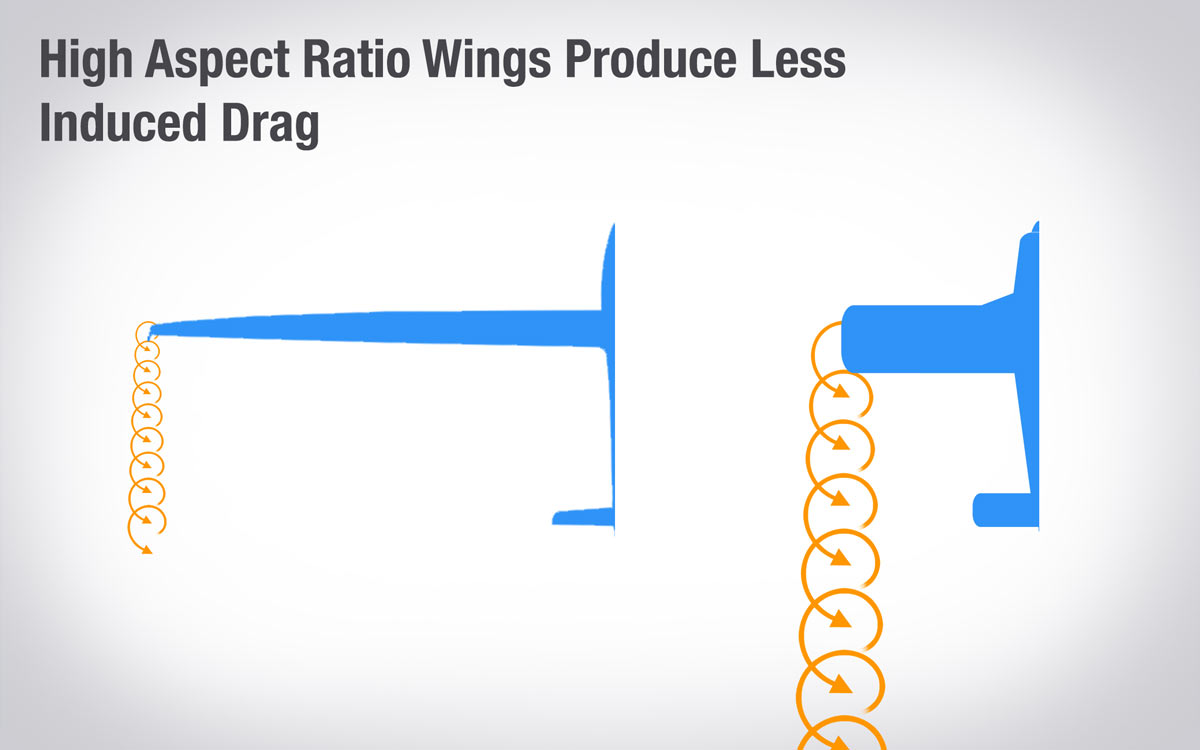

With keeping the surface area same, they can reduce drag by extending the wing. As the wing is extended, the amount of air spillage(due to pressure difference) is less from bottom of the wing to top of the wing.

These so called wingtip vortices try to pull back the aircraft because its a drag force (called induced drag) acting opposite to thrust.

When you have a reduced wing tip area, then the amount of spill is less and thus drag is reduced.

Still why do we need to extend the wing? Can't we just make the wing tips short?

Well, surface area directly effects lift force. It's one of the parameters. So when you cut short a wing's tip, the surface area decreases. That does not help gaining lift. We need a way to keep the surface area constant and then make the wing tips short. And the solution is the design of "Aspect Ratios".

If high aspect ratios provide high lift to drag ratio, then why in the world we need low aspect ratio wings?

Because having high lift to drag ratio is sometimes not the priority.

Speed is. Maneuverability is. Fuel storage space is.

What do you think is the aspect ratio of this F-102 Starfighter:

It's 2.35.

It's not efficient. It has a poor lift to drag ratio than a Cessna 172.

Then why are they designed like this?

They are designed for the speed.

So, to compensate decreased surface area; velocity is increased.

F-102 was the first aircraft to break Mach 2.

So is the Bell X-1 which broke the sound barrier in October, 1947 for the first time in history. Did it have a high aspect ratio?

Nope. Aspect ratio of Bell X-1 was " 4 ".

SR-71 Blackbird flew at Mach 3 with an aspect ratio of 1.7.

As you know, SR-71 is a legend. It was from the legendary Skunk Works where everything fly fast and high.

There is another aircraft from Skunk Works that fly high (above 70,000ft) with an aspect ratio of 14.

That's right - 14.

That is 9 times more than the aspect ratio of SR-71, and it still flies above 70,000ft.

And that aircraft is the private jet of NSA & CIA. :)

The one and only Lockheed U-2.

U-2 is a subsonic surveillance aircraft. And when operating at high altitudes, the density of air is less and they don't have the luxury of high speed. The requirement to produce tremendous lift is the highest priority. So in order to compensate, Lockheed engineers gave an high aspect ratio wing to U-2; thereby increasing the surface area and reducing drag.

Most of the surveillance aircraft that operates at high altitude, where air is scarce, uses high aspect ratio wing.

Commercial airliners need speed as well as lifting capability. So they settle to have an aspect ratio somewhere between 6 and 10.

Boeing 747 has an aspect ratio of 6.96.

Finally, here is a chart plotted between Mach No. and Aspect Ratio.

You can see from here that aircraft that has a high aspect ratio has speeds below mach 1.

Aspect ratios are great. By looking at just it's value, we can tell lot about the planes that have them.

Thank You for reading guys.

CK